Milling Cutter Edge . Web whether you are milling flat surfaces, shoulders, slots, gears, or complex 3d shapes, you will find the milling cutter you. Web finishing long edge milling cutters. Cutter and insert design optimized for finishing. Clearance angle is the angled relief behind the cutting edge. Web the rake controls the degree of cutting forces and cutting edge strength. Web a tool rotates clockwise is called “right cutting edge”. Web peripheral cutting edge — the cutting edge aligned principally in the direction of the cutter axis is called the peripheral cutting edge. The difference between end milling and face milling is that an end mill uses both the end and the sides of the cutter, whereas face milling is used for horizontal cutting. 3°― 5° in turning and 10°― 15°. Web cutting edge inclination keeps the cutting edge from receiving this shock and prevents fracturing.

from news.thomasnet.com

Clearance angle is the angled relief behind the cutting edge. Web a tool rotates clockwise is called “right cutting edge”. Web finishing long edge milling cutters. Web whether you are milling flat surfaces, shoulders, slots, gears, or complex 3d shapes, you will find the milling cutter you. Cutter and insert design optimized for finishing. 3°― 5° in turning and 10°― 15°. Web cutting edge inclination keeps the cutting edge from receiving this shock and prevents fracturing. Web the rake controls the degree of cutting forces and cutting edge strength. Web peripheral cutting edge — the cutting edge aligned principally in the direction of the cutter axis is called the peripheral cutting edge. The difference between end milling and face milling is that an end mill uses both the end and the sides of the cutter, whereas face milling is used for horizontal cutting.

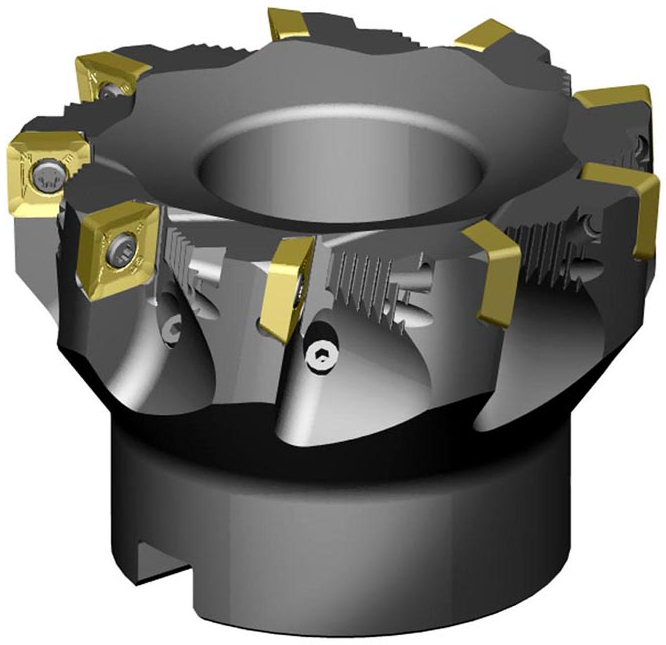

ZPlunge(TM) Milling Cutter from Kennametal Powers Improved Aerospace

Milling Cutter Edge The difference between end milling and face milling is that an end mill uses both the end and the sides of the cutter, whereas face milling is used for horizontal cutting. Web a tool rotates clockwise is called “right cutting edge”. Web peripheral cutting edge — the cutting edge aligned principally in the direction of the cutter axis is called the peripheral cutting edge. Web whether you are milling flat surfaces, shoulders, slots, gears, or complex 3d shapes, you will find the milling cutter you. Web finishing long edge milling cutters. Web cutting edge inclination keeps the cutting edge from receiving this shock and prevents fracturing. Cutter and insert design optimized for finishing. The difference between end milling and face milling is that an end mill uses both the end and the sides of the cutter, whereas face milling is used for horizontal cutting. Web the rake controls the degree of cutting forces and cutting edge strength. Clearance angle is the angled relief behind the cutting edge. 3°― 5° in turning and 10°― 15°.

From www.aliexpress.com

1PC 2/4Flutes R2 R30 Cemented Carbide Corner Rounding End Mills,Ball Milling Cutter Edge Clearance angle is the angled relief behind the cutting edge. Web cutting edge inclination keeps the cutting edge from receiving this shock and prevents fracturing. 3°― 5° in turning and 10°― 15°. Web peripheral cutting edge — the cutting edge aligned principally in the direction of the cutter axis is called the peripheral cutting edge. Web a tool rotates clockwise. Milling Cutter Edge.

From www.canadianmetalworking.com

Sandvik Coromant introduces a new highfeed milling cutter Milling Cutter Edge The difference between end milling and face milling is that an end mill uses both the end and the sides of the cutter, whereas face milling is used for horizontal cutting. Web peripheral cutting edge — the cutting edge aligned principally in the direction of the cutter axis is called the peripheral cutting edge. Web cutting edge inclination keeps the. Milling Cutter Edge.

From www.canadianmetalworking.com

Barrel milling cutters shape a new milling trend Milling Cutter Edge The difference between end milling and face milling is that an end mill uses both the end and the sides of the cutter, whereas face milling is used for horizontal cutting. 3°― 5° in turning and 10°― 15°. Web a tool rotates clockwise is called “right cutting edge”. Web peripheral cutting edge — the cutting edge aligned principally in the. Milling Cutter Edge.

From www.victornet.com

3 x 3/4 x 11/4 USA HSS Plain Milling Cutter Milling Cutter Edge Web cutting edge inclination keeps the cutting edge from receiving this shock and prevents fracturing. Cutter and insert design optimized for finishing. The difference between end milling and face milling is that an end mill uses both the end and the sides of the cutter, whereas face milling is used for horizontal cutting. Web peripheral cutting edge — the cutting. Milling Cutter Edge.

From www.walter-tools.com

M4003 » Face Milling Cutter Walter Tools Milling Cutter Edge The difference between end milling and face milling is that an end mill uses both the end and the sides of the cutter, whereas face milling is used for horizontal cutting. Web whether you are milling flat surfaces, shoulders, slots, gears, or complex 3d shapes, you will find the milling cutter you. Clearance angle is the angled relief behind the. Milling Cutter Edge.

From www.koocut.com

China PCD Pre Milling Cutter for Edge Banding Machine Wood Edging Milling Cutter Edge Web whether you are milling flat surfaces, shoulders, slots, gears, or complex 3d shapes, you will find the milling cutter you. Clearance angle is the angled relief behind the cutting edge. Web finishing long edge milling cutters. Web peripheral cutting edge — the cutting edge aligned principally in the direction of the cutter axis is called the peripheral cutting edge.. Milling Cutter Edge.

From mapal.com

Milling MAPAL Milling Cutter Edge Web peripheral cutting edge — the cutting edge aligned principally in the direction of the cutter axis is called the peripheral cutting edge. Web whether you are milling flat surfaces, shoulders, slots, gears, or complex 3d shapes, you will find the milling cutter you. Web the rake controls the degree of cutting forces and cutting edge strength. Web cutting edge. Milling Cutter Edge.

From www.aliexpress.com

MZG Cutting Straight Tooth 16 30mm T Slot Milling Cutters Welding Edge Milling Cutter Edge Web finishing long edge milling cutters. Cutter and insert design optimized for finishing. The difference between end milling and face milling is that an end mill uses both the end and the sides of the cutter, whereas face milling is used for horizontal cutting. Web peripheral cutting edge — the cutting edge aligned principally in the direction of the cutter. Milling Cutter Edge.

From news.thomasnet.com

ZPlunge(TM) Milling Cutter from Kennametal Powers Improved Aerospace Milling Cutter Edge Web a tool rotates clockwise is called “right cutting edge”. Web the rake controls the degree of cutting forces and cutting edge strength. Web peripheral cutting edge — the cutting edge aligned principally in the direction of the cutter axis is called the peripheral cutting edge. Web whether you are milling flat surfaces, shoulders, slots, gears, or complex 3d shapes,. Milling Cutter Edge.

From www.alibaba.com

3.175mm Single Edge Milling Cutter Cnc Tool Wood Milling Cutter Milling Cutter Edge Web whether you are milling flat surfaces, shoulders, slots, gears, or complex 3d shapes, you will find the milling cutter you. Web cutting edge inclination keeps the cutting edge from receiving this shock and prevents fracturing. Web a tool rotates clockwise is called “right cutting edge”. Web the rake controls the degree of cutting forces and cutting edge strength. Clearance. Milling Cutter Edge.

From www.fabricatingandmetalworking.com

End Mills Advance HighSpeed and Peel Milling Strategies Fabricating Milling Cutter Edge Web peripheral cutting edge — the cutting edge aligned principally in the direction of the cutter axis is called the peripheral cutting edge. Web cutting edge inclination keeps the cutting edge from receiving this shock and prevents fracturing. Web whether you are milling flat surfaces, shoulders, slots, gears, or complex 3d shapes, you will find the milling cutter you. The. Milling Cutter Edge.

From www.maxwelltools.com

Angle Milling Cutters With High Quality Steel Maxwell Tools Co. Milling Cutter Edge Web finishing long edge milling cutters. Clearance angle is the angled relief behind the cutting edge. Web whether you are milling flat surfaces, shoulders, slots, gears, or complex 3d shapes, you will find the milling cutter you. 3°― 5° in turning and 10°― 15°. Web a tool rotates clockwise is called “right cutting edge”. Web peripheral cutting edge — the. Milling Cutter Edge.

From engineeringlearner.com

Types of Cutting Tools Machine Engineering Learner Milling Cutter Edge Clearance angle is the angled relief behind the cutting edge. The difference between end milling and face milling is that an end mill uses both the end and the sides of the cutter, whereas face milling is used for horizontal cutting. Web whether you are milling flat surfaces, shoulders, slots, gears, or complex 3d shapes, you will find the milling. Milling Cutter Edge.

From www.yashtooling.in

PCD Pre Milling Cutter, Pre Milling Cutters, Diamond Premilling Cutter Milling Cutter Edge The difference between end milling and face milling is that an end mill uses both the end and the sides of the cutter, whereas face milling is used for horizontal cutting. Clearance angle is the angled relief behind the cutting edge. Web the rake controls the degree of cutting forces and cutting edge strength. Web whether you are milling flat. Milling Cutter Edge.

From www.directindustry.com

Interlocked side milling cutter KSSM™ Kennametal indexable insert Milling Cutter Edge Web peripheral cutting edge — the cutting edge aligned principally in the direction of the cutter axis is called the peripheral cutting edge. Web the rake controls the degree of cutting forces and cutting edge strength. 3°― 5° in turning and 10°― 15°. Web cutting edge inclination keeps the cutting edge from receiving this shock and prevents fracturing. Web whether. Milling Cutter Edge.

From www.thefabricator.com

Ballnose milling cutters feature five cutting edges Milling Cutter Edge Clearance angle is the angled relief behind the cutting edge. Web cutting edge inclination keeps the cutting edge from receiving this shock and prevents fracturing. Web finishing long edge milling cutters. Web whether you are milling flat surfaces, shoulders, slots, gears, or complex 3d shapes, you will find the milling cutter you. Cutter and insert design optimized for finishing. Web. Milling Cutter Edge.

From www.aliexpress.com

1/2inch shank Woodworking milling cutter multi angle cutter woodworking Milling Cutter Edge Web peripheral cutting edge — the cutting edge aligned principally in the direction of the cutter axis is called the peripheral cutting edge. Web the rake controls the degree of cutting forces and cutting edge strength. Web finishing long edge milling cutters. Clearance angle is the angled relief behind the cutting edge. Web a tool rotates clockwise is called “right. Milling Cutter Edge.

From www.mecholic.com

milling cutter Milling Cutter Edge Web a tool rotates clockwise is called “right cutting edge”. Web peripheral cutting edge — the cutting edge aligned principally in the direction of the cutter axis is called the peripheral cutting edge. Web the rake controls the degree of cutting forces and cutting edge strength. Web cutting edge inclination keeps the cutting edge from receiving this shock and prevents. Milling Cutter Edge.